Equipment is regularly calibrated and serviced, ensuring we supply authentic certification in all supporting documentation for every welding project.

Welding

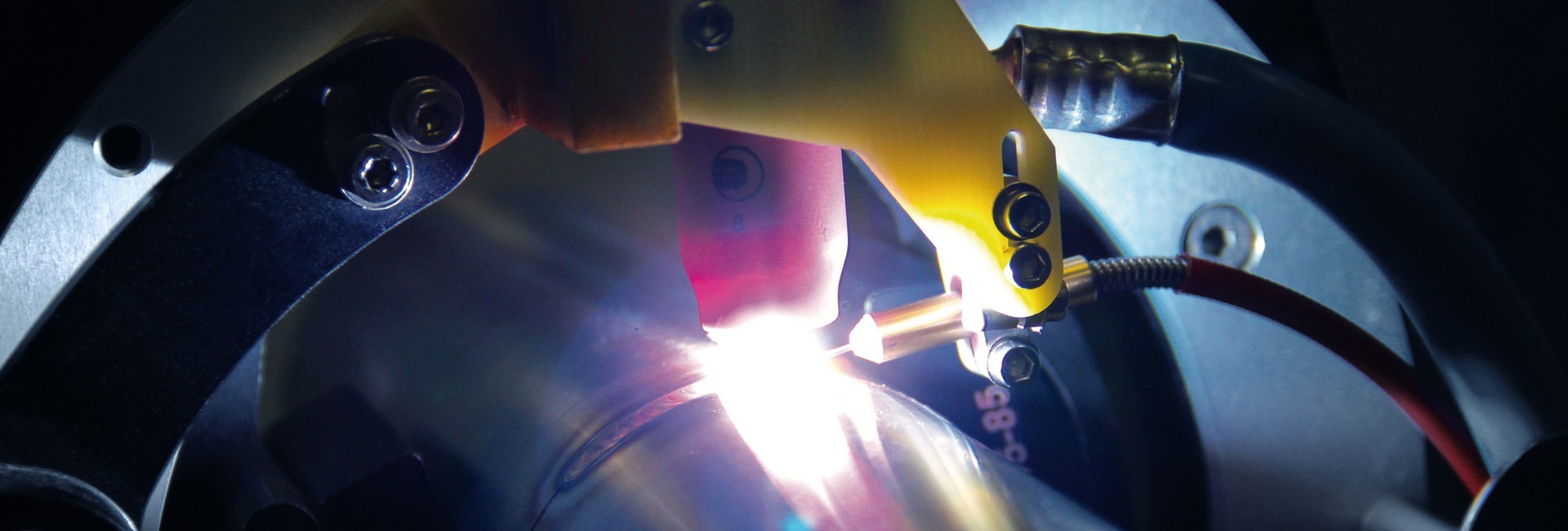

Orbital Welding

Matini owns Orbitec model EVO 200 WP and Arc Machine Incorporated (AMI) 207 Model welding plants. All include their own welding heads and collets, enabling us to work at multiple ‘clean room’ sites simultaneously.

Cooling Unit attaches to the base of Model 207 or 227 power supply, features a heavy duty pump, flow sensor and ultra-violet water purifier. Powered by an outlet in the mating power supply, it provides a recirculating coolant source for water-cooled weld heads, allowing welding of heavy-wall tube or high-duty cycle welding.

External Memory Module stores up to 100 weld schedules (in non-volatile memory) for safekeeping or transfer of weld schedules between machines.

Remote Operator Pendant allows remote operation of power supply controls for: weld/test mode; sequence start/stop; manual purge; motor jog; print; weld schedule access; amps up/down; and all-stop. It comes with a 25ft (8m) cable and additional extension cables are also available.

Tungsten Electrodes Matini’s own precision ground, cut-to-length electrodes increase weld repeatability and last longer than those not machined to the same exacting standards. These electrodes are constructed from non-radioactive Sylvania 2% ceriated Tungsten.

Off-set Electrode Holders (Mushroom) reposition the electrode axially from the centre of the weld head closer to one side, thereby reducing the stick-out length of fittings and valves. A simple solution for difficult applications, the holders are available in 90° (fixed) and adjustable angles.

TIG Welding

We offer manual welding processes for pipework in general service areas via Tungsten Inert Gas (TIG) welding of thin wall and schedule pipe wall thickness fully purged, with full documentation and traceability.

All stainless steel welding undergoes a full Argon purge to ensure that all welds meet our high standards.